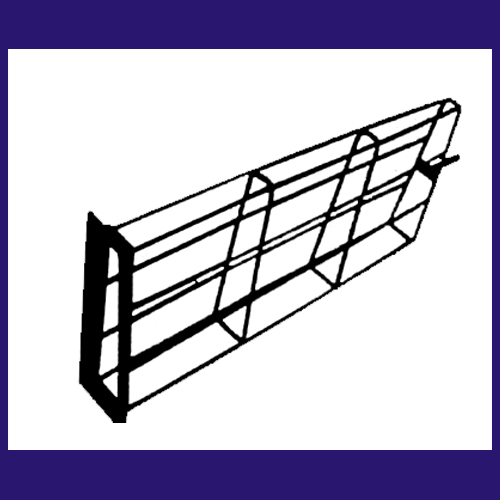

Trapezoidal bag cage

1. Overview of dust bag keel:

The dust removal skeleton is the rib of the filter bag, it should be light and easy to install and maintain, and the quality of the frame directly affects the filtration state and service life of the filter bag. It adopts natural granite, which is machined into a round curved plate, and the overall structure is smooth and flat. It has the characteristics of erosion resistance, wear resistance and high temperature resistance. The exterior is poured with high-strength, high-temperature resistant and acid-alkali-resistant materials. The outer steel plate of the cylinder equipment greatly enhances the strength and service life of the equipment. The body adopts a structure of 1 meter per section, and there are concave and convex joints at the interface of each section, and furan resin or acid-alkali-resistant cement is used to connect at the seam during installation to ensure that the connection does not leak; It overcomes the common problem of water leakage and air leakage in the joints of the original granite dust collector. The upper sink is a ceramic structure, and the ceramic dust collector ensures no leakage during the water supply process, which avoids the setback of water seepage in the sink of the original granite dust collector and enhances the use effect of the dust collector. The installation is simple, generally 1 meter per section, and the installation can be completed in half a day on site hoisting, which reduces the construction period.

2. Specifications:

Rotundity. Oval. Flat. Envelope-shaped. Trapezium. Star. Spring type: Other types of dust removal skeleton customized according to customer requirements.

3. Structure:

There are multiple knots. Venturi tube. Protect the short tube. Down-loading type. Plug-in type. Reasonable structure such as chuck type.

4. Surface treatment:

There is galvanizing. Spraying. Anti-corrosion treatment. Surface silicone spraying, etc. Surface silicone coatings are particularly suitable for dust collector applications in large generator sets.

Author of the bag cage standard T/CAEPI4-2017

- Fully automated process, bag cage output up to 45,<> meters per month.

- Have a complete team with more than 15 years of experience in the cage bone industry.

- Domestic advanced bag cage manufacturing technology

- Perfect quality control system and inspection equipment

- Exclusive customized catenary type shot blasting pretreatment equipment

- We can produce a full range of bag cage products at home and abroad